& Marine Ops

Automated

Inventory (AIM)

Autonomous

Functions

Battery

Technology

Carbon

Capture

Nuclear

Power

AR Safety

Marine Envs

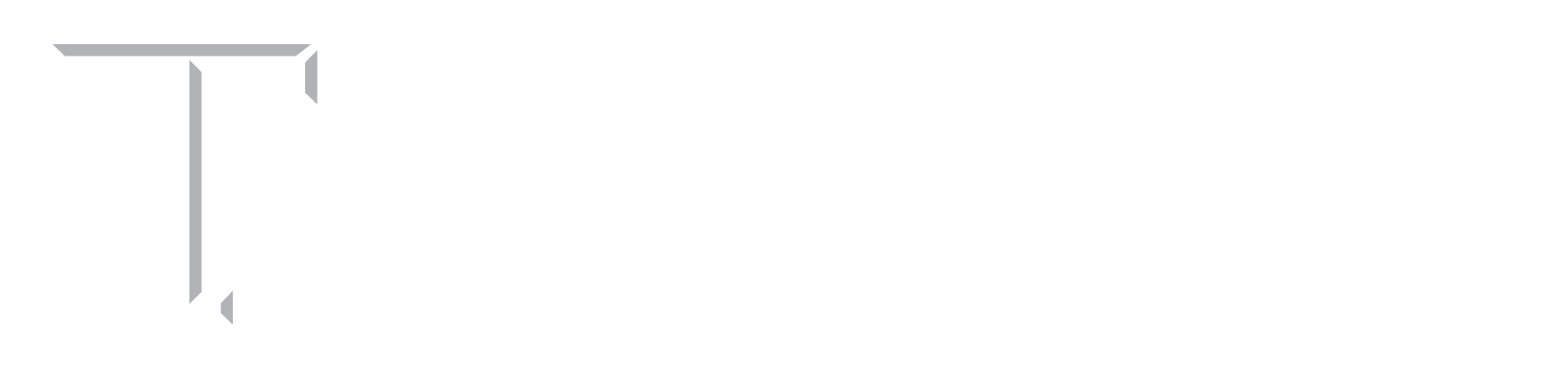

Cryogenic ammonia releases are of keen interest to determine needed computational fluid dynamics (CFD) variables. As part of this process several lab-scale experiments and Verification and Validation(V&V) studies are being used to determine best practices for models and simulations of ammonia leaks. The experimental work is examining ammonia releases over a water body in a variety of conditions.

Ammonia tank with exit valve

Ammonia tank without exit valve

Preparations are being made to advance the lab-scale tests to larger tests (similar to the Jack Rabbit or Red Squirrel tests but over water).

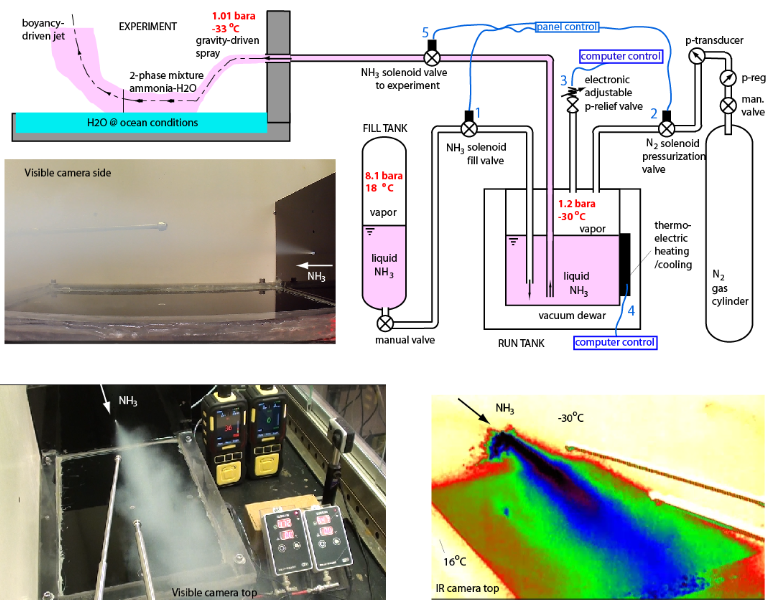

The research effort took ship-survey 360-degree Fish Eye camera videos of Kennedy Ship assets and extracted image frames to classify each image. Image classification was performed and involves labeling each image vas the most important object of interest in the image.

These image frames were painstakingly annotated for each image with a bounding box around each object of interest (Object Detection). It has been demonstrated that Object Detection (even on 360 Degree Fish Eye camera images) is possible if data annotation is carefully carried out.

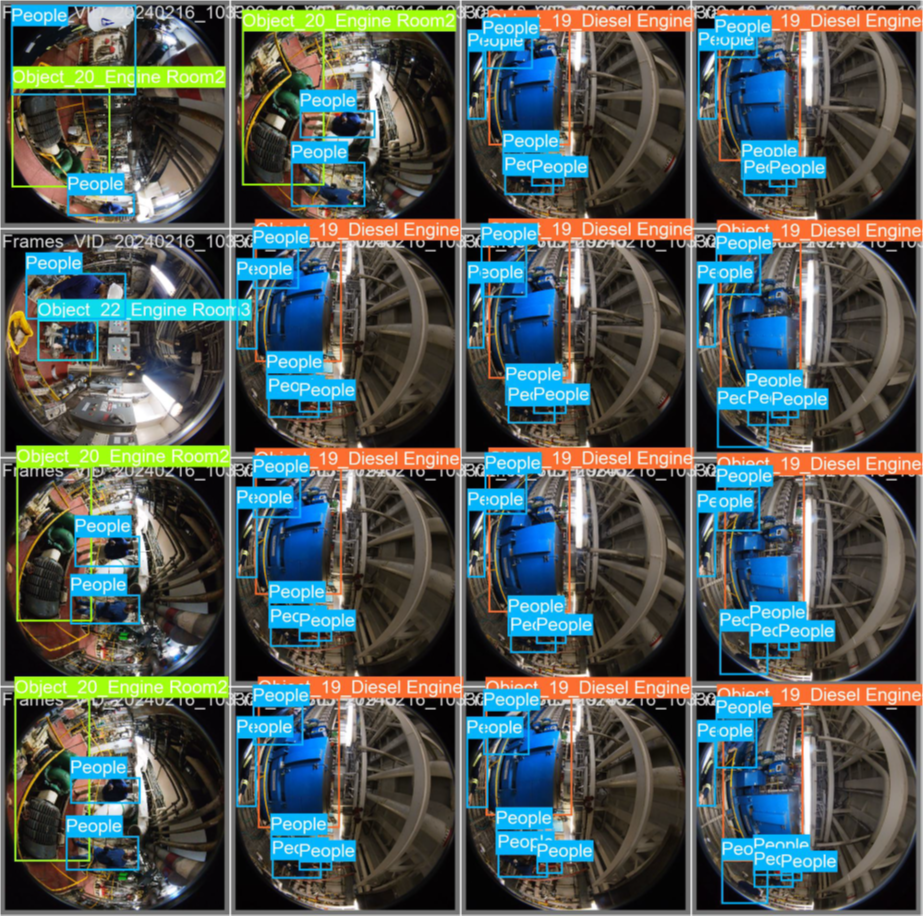

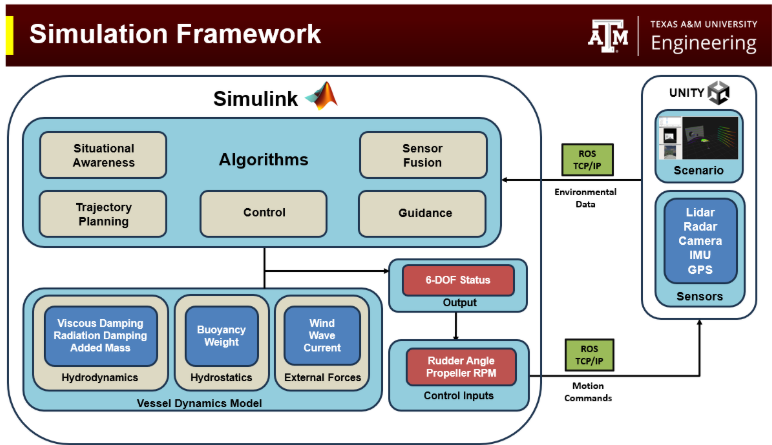

The implementation of autonomous systems poses substantial challenges, including high development costs, logistical complexities, and the inherent risks of real-world testing. Replicating rare or extreme conditions—such as severe weather, equipment malfunctions, or collision scenarios—safely and economically adds to these difficulties.

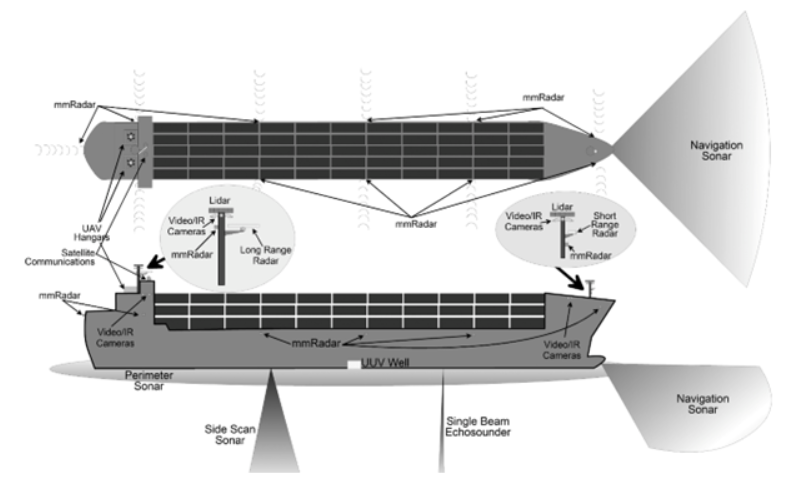

Vessel Dynamic Models

Simulation Framework

Sensors

Test Scenarios

Imazu Test Scenarios

To address these challenges, this work presents a modular, high-fidelity simulation framework designed to provide a controlled and cost-effective virtual environment for the testing and certification of autonomous systems.

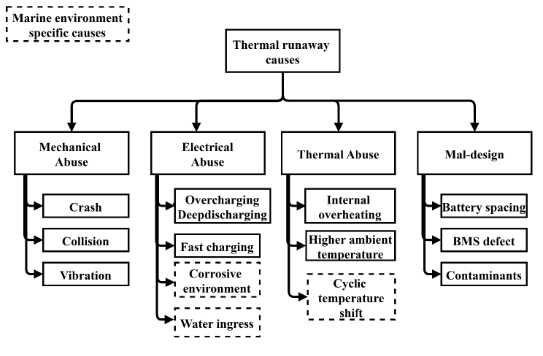

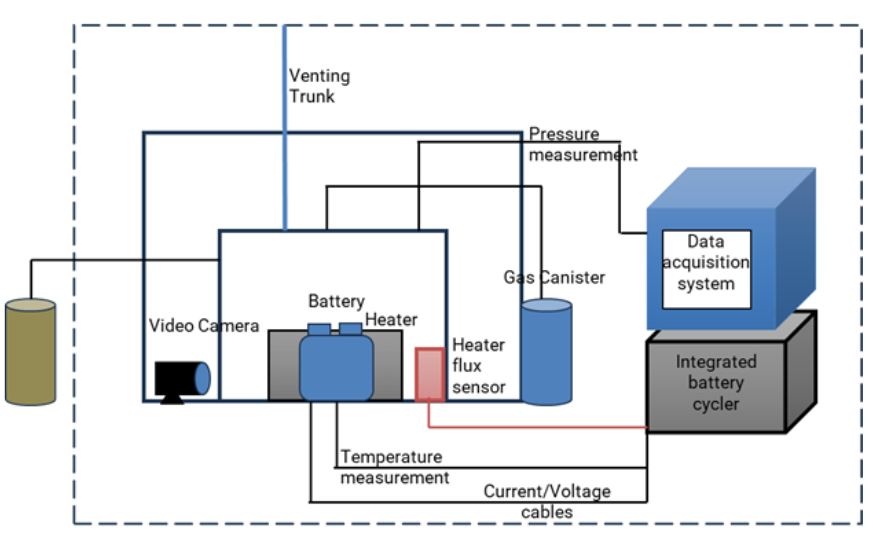

Next-generation batteries show promising potential but are not ready for direct implementation in offshore and marine applications. This is primarily due to several challenges: low TRL, limited understanding of thermal runaway behavior, insufficient research on gas generation and explosion hazards, and the lack of a robust safety management strategy for large-scale applications. Additionally, recurring explosions and rekindling of fire following the initial suppression of a battery fire remain poorly understood. To address these challenges, detailed research, and large-scale field tests are crucial to ensuring safe operation and facilitating wider adoption of these technologies.

Battery ABS Paper Images

Click Here

Specific energy density range based on development of various battery types

Accident cause analysis for 140 Lithium-Ion Battery(LIB) Thermal Runaway(TR) incidents

Classification of identified LIB fire causes

ARC Setup

Nuclear-powered ships are being considered for a wide range of applications – ice breakers, container ships, military vessels, etc. The recent advances in nuclear power options has created the need to evaluate and look at the alignment between these power units and the power needs and safety needs on a vessel.

Cross-sectional schematic of

a nuclear ship’s reactor containment system

Several reactor configurations exist. Above is the Air-Brayton

Power Conversion System. The power conversion system drives the

size of the nuclear reactors

The augmented reality(AR)/ mixed reality(MR)/ extended reality(XR) (honestly, it seems like “any letter” followed by R) project aims at sustaining and reinforcing the workers’ safety and situation awareness as they perform their routine tasks using XR technologies in industrial settings. The objective is to develop XR enhancements that assist the workers in their tasks without introducing additional risk factors.

Sound Level Warning

RealWear Condition

Phone Condition 2

Sound Warning

HoloLensCondition

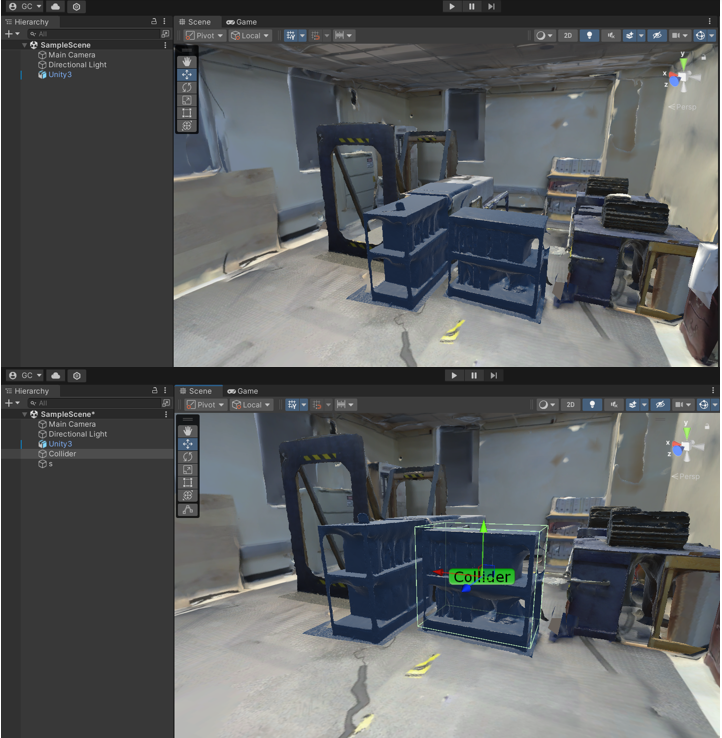

Part of the research included the creation of a digital twin of ship aspects (e.g., binders, trip hazards, head knockers, wet spots, valves, noise, etc.) in an experiment room. The purpose of the digital twin is to provide contextual information for the developed systems of each aim, effectively replacing real-time environmental understanding. The goal is to evaluate the proposed systems in a controlled environment to ensure their correct functionality before implementation in a real-world setting. This section discusses the creation of the digital twin and its implementation in Unity.

3D Element Scanning

Detailed models of key elements

Scale environment in Unity

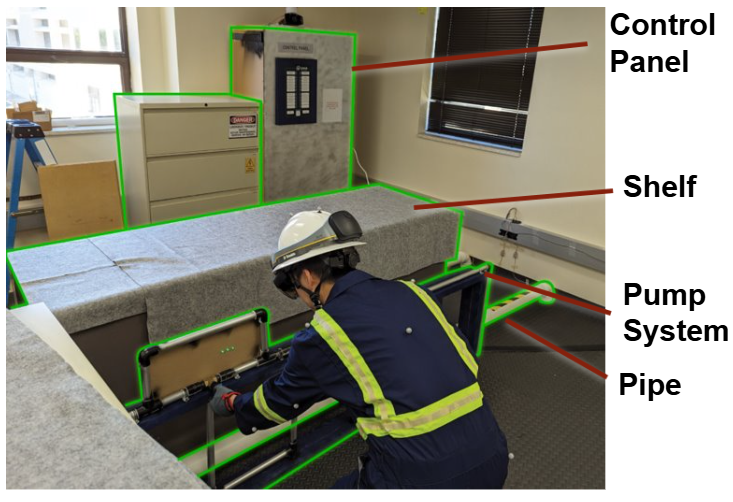

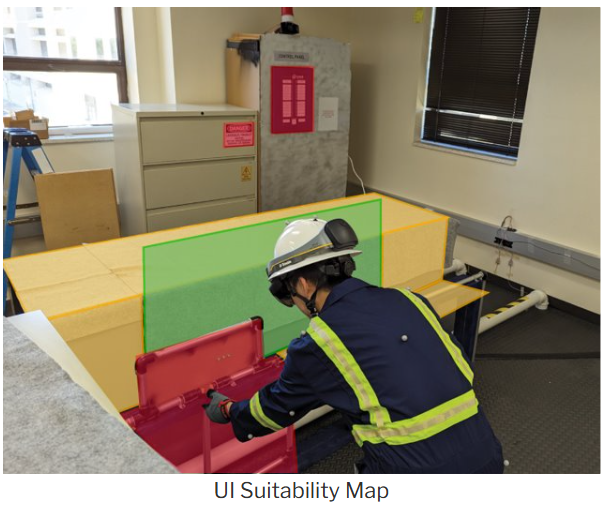

Dynamic Adaptation of UI Features

Environment Understanding

UI Optimization Components

Before the alarm

During the alarm

Sound Warning

ABS Paper Images

Click Here

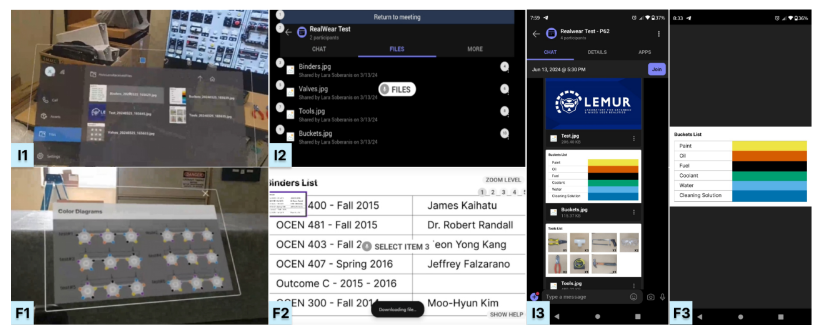

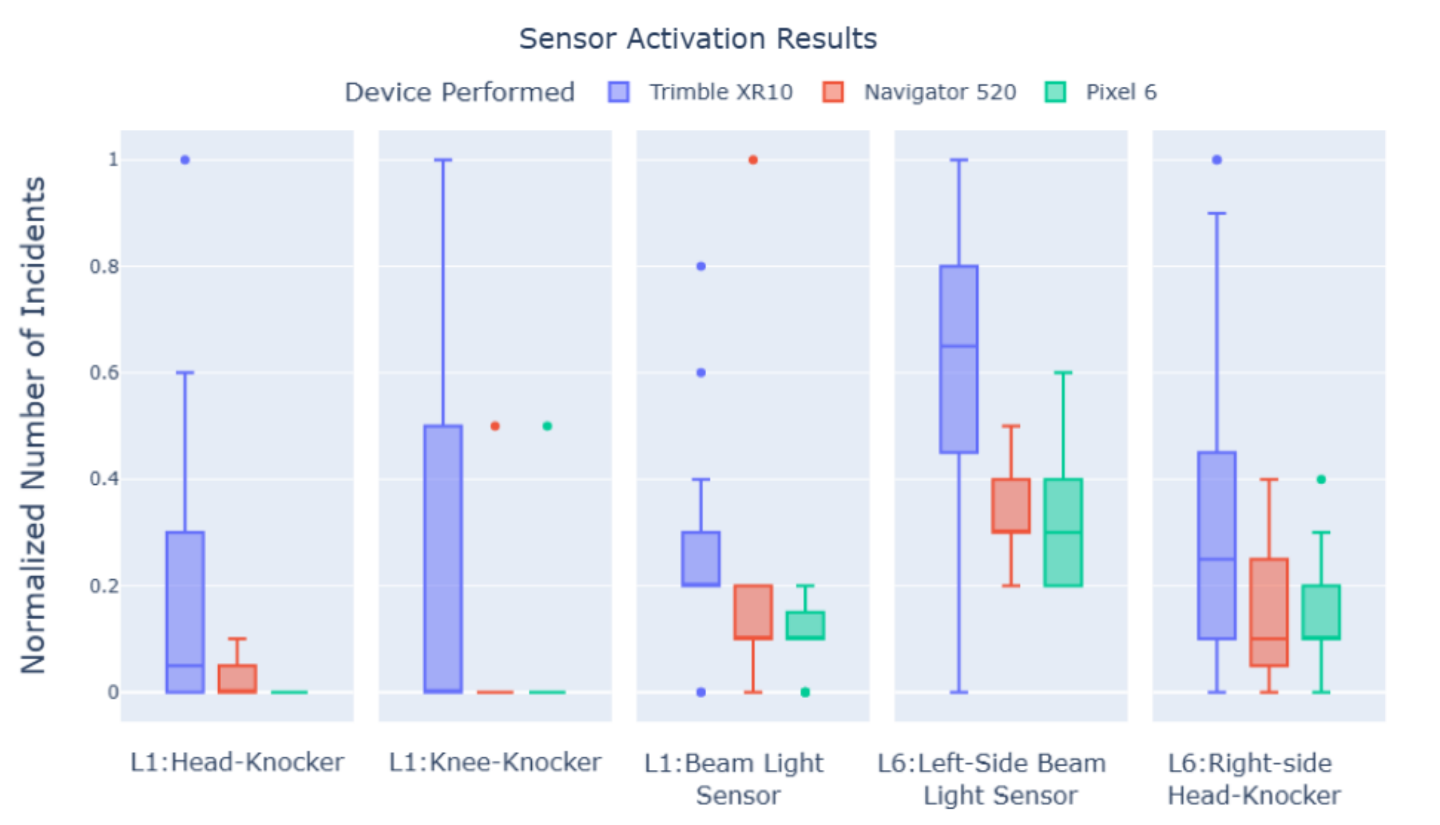

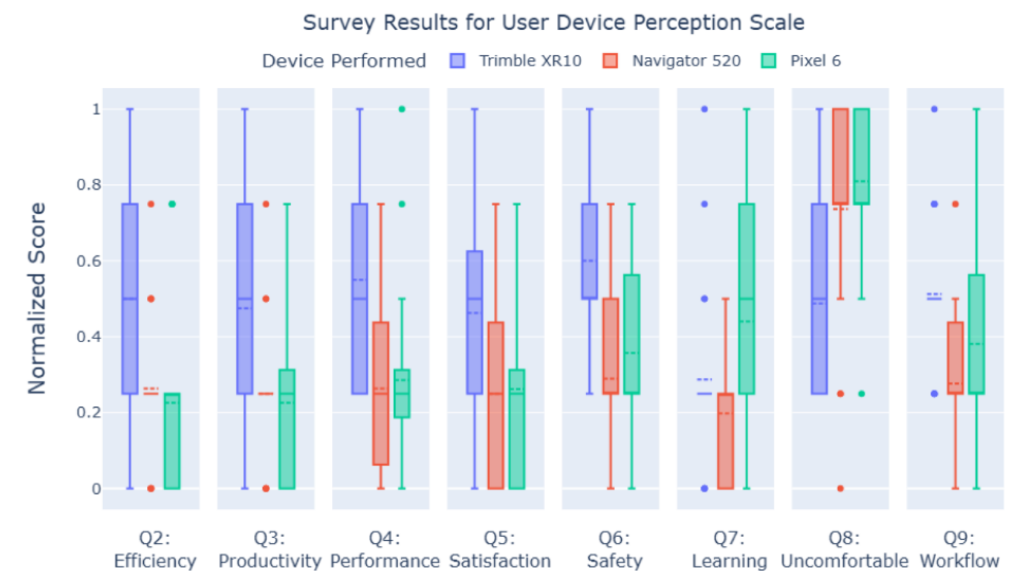

Participants performed various tasks within a simulated industrial hazardous environment while using either one of two off-the-shelf Augmented Reality-Head-Mounted Displays

Tasks(T1-T5) and their associated locations(l1-L6)

Microsoft Teams interface to access the files(I1-I3) and first-person view

visualization of the files (F1-F3)

Sensor normalized number of incidents that reported statistically

significant differences between the conditions.

Normalized User Device Perception scores reveal statistically

significant differences between conditions

Normalized System Usability Scale and NASA TLX scores that reported statistically significant differences between the conditions